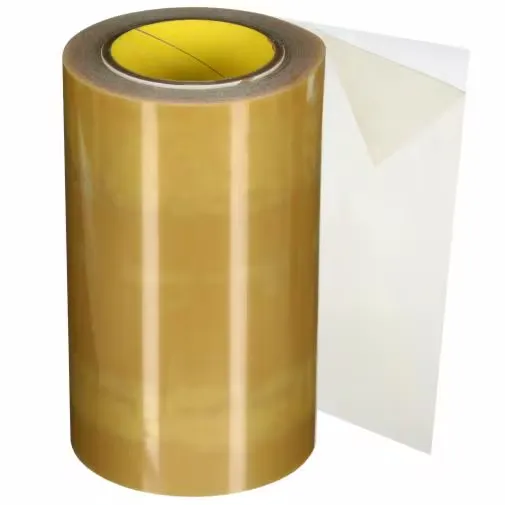

3M 583 Heat activated double-sided nitrile phenolic adhesive tape

- Heat or solvent activation

- Good flexibility

- Slightly tacky

- Custom die-cuttable

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

3M 583 heat activated adhesive film for printed circuit boards

3M 583 is a reactivatable heat-curing adhesive film made from nitrile phenolic resin, engineered for high bond strength across a wide range of materials.

Its flexibility, thin profile, and ability to be custom die-cut make it ideal for electronics, automotive, aerospace, and signage applications.

3M 583 is delivered as a thin, slightly tacky film, allowing for easy pre-positioning before bonding. To achieve full adhesive strength, it must be activated by:

Heat, between 107°C and 149°C under pressure

Or appropriate solvents for temperature-sensitive assemblies

After bonding, the film can be crosslinked to enhance its thermal and chemical resistance. This is done by heating the bonded assembly at 177°C for 8 minutes or 110°C for 4 to 15 hours.

Key benefits of 3M 583

High-performance thermosetting adhesive film

Activates with heat or solvents

Flexible and easily die-cut

Withstands high temperatures after curing

Strong adhesion to metals, plastics, and fabrics

Suitable for structural bonding in demanding environments

Typical applications of 3M 583

Electronic component assembly

Splicing glass fabrics in PCB manufacturing

Bonding technical films or foils

Electrical insulation in devices

Industrial laminations requiring precision and strength

Composite part fabrication

Why choose 3M 583?

✔ Versatile: Compatible with multiple substrates and activation methods

✔ Durable: Resists mechanical and thermal stress

✔ Precise: Thin film for high-accuracy applications

✔ Flexible: Conforms to complex shapes without tearing

✔ Reliable: Long-lasting adhesion even under extreme conditions

Technical data – 3M 583 bonding tape

| Property | Value |

|---|---|

| Adhesive type | Nitrile-phenolic |

| Adhesive film thickness | 0.05 mm |

| Release liner | 0.05 mm polyester film |

| Pre-activation appearance | Slightly tacky |

| Elongation before curing | Up to 800% |

| Peel strength on stainless steel | ~2.9 N/mm after 72h at room temperature |

| Dielectric strength | 990–3,000 V/mil (~39–118 kV/mm) |

| Max operating temperature | Up to 150°C (higher after crosslinking) |

| Activation methods | Heat (107–149°C) or solvents |

| Crosslinking temperatures | 177°C for 8 min or 110°C for 4–15 hours |

| Shelf life at 23°C | 6 months |

| Shelf life at ≤ 4°C | 18 months |