Masking / Paint protection with adhesive tape

- Clear delineation

- Removable without residue

- Paint masking, shot-blasting, sand-blasting

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Paint protection with shot-blasting and sand-blasting

Sandblasting and shot blasting consist in removing material from an object in order to change the material’s surface by projecting abrasive particles at high pressure (grit, sand, corundum…). Some parts don’t need to be subjected to this treatment and can be protected (for example a thread on a mechanical part) by means of adhesive tape resistant to abrasion which can be removed without leaving any marks. The adhesive tape range for masking and shot blasting is broad in order to meet two main parameters : type of abrasive and pressure. It is mainly cloth tapes and PVC tapes that can meet these two applications.

A list of the main materials used for mechanical treatments follows :

- Rectangular steel shot

- Corundum

- Steel balls

- Glass beads

- Plastic pellets

- Ceramic beads

For each of these applications, suitable masking products exist. To choose the best product, you should know the maximum pressure (4 to 8 bars), the type of the projected material and the projection time on the protected area.

Protection for electroplating

The principle of electroplating is to do surface treatment with a deposit of material through electrolysis. In order to mask for an electrolyte bath, a conductive adhesive tape that is resistant to chemical attack is needed. The most suitable products to meet these constraints are aluminium tapes, lead tapes and vinyl adhesive tapes.

Here is a list of the main existing treatments :

- Silvering / gilding

- Cadmium

- Galvanization

- Copper plating and brass plating

- Tinning

- Plating

- Chrome plating

- Hard chrome plating

- Anodising

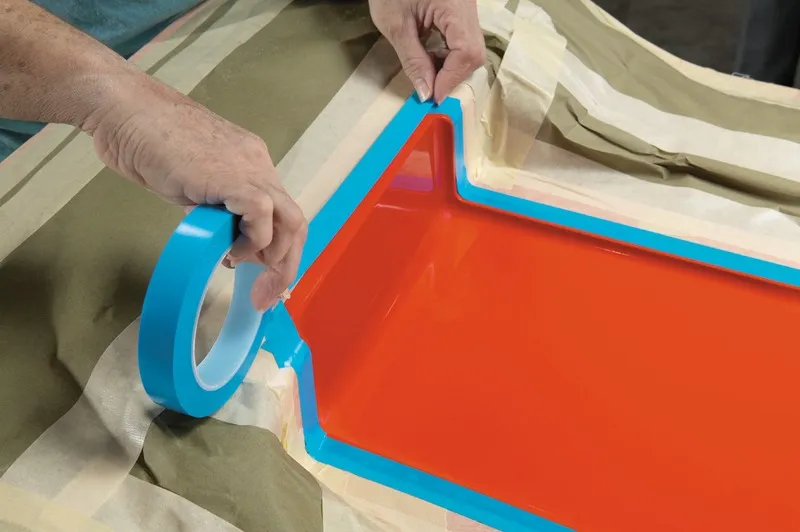

Liquid paint masking

Masking for liquid paint is the most common and most used masking, particularly in painting applications in the building industry and for road markings. Mainly single sided paper adhesives and single sided PVC adhesives are used for these applications. We can separate the liquid paint into 2 categories :

- Solvent based paint

- Water based paint

For these two categories, the corresponding adhesive products will differ according to the temperature resistance and conformability.

Powder coating masking

Epoxy or polyester powder coating is a widely used industrial process to spray electrostatically charged paint in powder form, and to put it in the oven to complete the process. To mask a section of the painted part, it is mainly single sided polyester adhesive tape that is used. Its polyester backing allows high temperature resistance, its silicone adhesive allows for removal without leaving any adhesive residue, and its thinness prevents the creation of deposits.

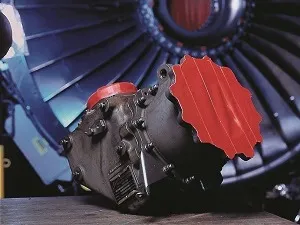

High temperature masking

Used in many industrial applications such as soldering composites, aeronautical insulation panels, masking connectors…. The various materials can withstand extreme heat and high temperatures : Polyimide - Kapton, Teflon - PTFE, polyester, glass cloth.... Most of these materials are covered with silicone or rubber thermosetting adhesive that provides good temperature resistance.

Among these treatments, here are the main ones :

- Protection before wave welding

- Metal spraying

- Chemical processing (Aluminium, Titanium, Alloys)

New: Our silicone-free masking tapes

![]()

Silicone-based adhesive tapes are traditionally used in extreme production environments. However, there is a risk of silicone migration to the substrate, which can threaten product quality and safety.

Eliminate these residue risks with our silicone-free masking tapes:

- Maintain high performance in harsh conditions

- Withstand extreme pressure and temperatures up to 180 °C

- Heavy-duty tapes, offering maximum reliability

- Reduce costs by eliminating time-consuming residue cleanup

Silicone-free masking tapes are the ideal solution for:

- Applications where a 100% silicone-free environment is required

- Applications with zero tolerated adhesive residue

- High temperature applications such as masking before bonding (masking areas before painting that then undergo a bonding or gluing process)

- Composite manufacturing and metal sandwich construction

Summary of benefits of silicone-free masking tapes:

- Easy, controlled, finger-friendly unwind, making it convenient to use

- Tear resistant with a strong PET/non-woven backing

- High performance adhesive capable of withstanding high pressures and temperatures up to 180 °C

- Excellent adhesion to rough surfaces

- Little ghosting/discoloration on clear coatings

- Superior paint edges in two-color applications

- Residue-free removal

Contact us for more information or a quote!

Examples of masking protection application

High temperature plasma masking. Reliable adhesion without residue. Resistance to harsh processes. Custom die-cutting