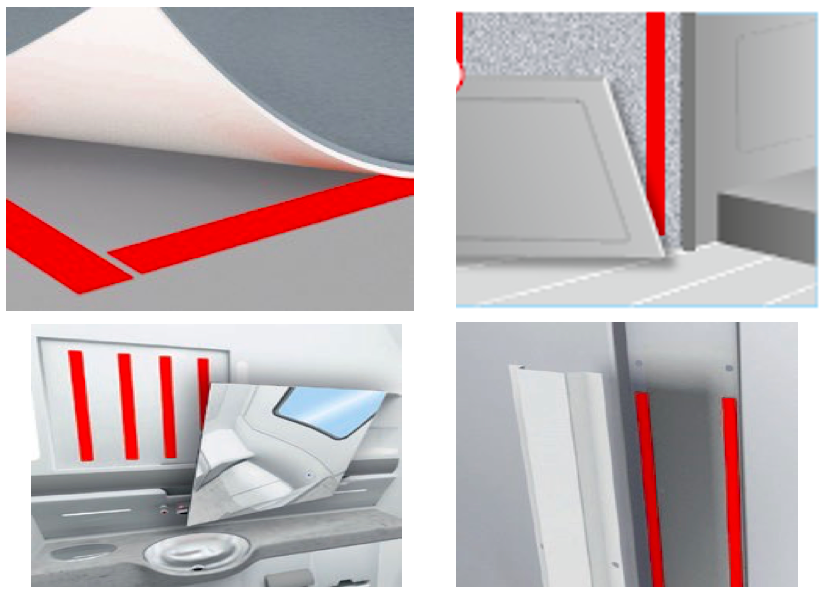

Fireproof assembly/bonding with flame retardant tape

- Adhesive tapes that comply with fire safety standards

- Slow burning or self-extinguishing materials

- Halogen-free product selection included for less toxicity

- High performance adhesives for demanding applications

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

High temperature, flame resistance, fireproofing: what is the difference?

High temperature adhesive tapesHigh-temperature adhesive tapes are used for their resistance in hot environments, generally from 150 °C. Thermal insulators (Kapton, glass cloth) can even withstand temperatures up to 316 °C. High-temperature tapes are used to mask and protect parts subjected to high temperatures during a cooking cycle, a passage in oven, for example.

| |

Flame resistant materialsFlame resistance means that a material is non-flammable by nature: this is the case of concrete, steel, glass...

The French classification is applied for the furnishing materials, the others are classified according to the euroclasses and the standard EN 13-501-1.

| |

Fire retardant tapesFire retardant materials are chemically treated to become non-flammable or flame retardant (slow burning or self-extinguishing). Fireproofing is a process that delays or stops the spread of flames. Flame retardant products are key players in passive fire protection and play a crucial role in everyday life as well as in industry. A flame retardant tape has been coated with a flame retardant substance that protects it from burning or heating up. Many industries use flame retardant pre-products to increase the safety of manufactured products.

|

What are the industry standards in terms of fire safety?

Adezif offers a range of double-sided adhesive tapes for fire-resistant fastening applications with strict fire protection requirements.

- UL94 : Flammability standard for plastics

- FMVSS 302 : Automotive flammability standard

- EN 81-58:2018-05 : Safety standards in construction

- EN 13501-1 : Fire resistance of building materials

- EN 13823 : French standard - reaction to fire tests of construction products

- EN 45545 : Fire resistance standards for railways

- FTP 2010 code - OMI : International Code For Application Of Fire Test Procedures (testing of parts and assemblies)

Why a selection of halogen-free flame retardant products?

Non-halogenated products are essential for passive fire protection:

- Reduction of smoke emission and toxicity of fire gases

- Smoke is the leading cause of fire-related deaths: 80% are caused by inhalation of toxic substances (cf. Inhalation injury as a prognostic factor for mortality in burn patients, El Helbawy et. Al, 2011.

- The halogen-free products are designed in anticipation of future national and international regulations, which tend to reduce the use of certain halogenated products.

The flame retardant products we offer comply with fire regulation standards and include halogen-free solutions that reduce smoke and gas toxicity.

Advantages of our fireproof adhesive tapes

- Wide range of thin flame retardant double sided tapes for lamination applications and PE and acrylic foam tapes for construction solutions

- A selection of halogen-free products to reduce toxic smoke emission

- Compliance and design to UL94 and FMVSS 302 industry standards

- High performance on a wide variety of surfaces

- Reliable and durable long-term attachment

- Multiple product types to meet all types of applications

What are the different types of fire retardant tapes?

| THIN DOUBLE-SIDED FIREPROOF TAPES | ||

|---|---|---|

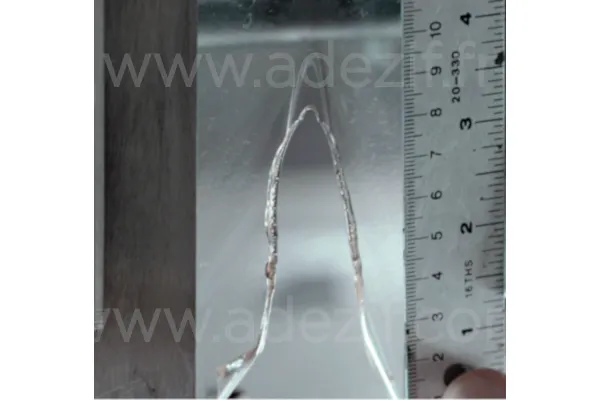

| Description | Thin double-sided flame retardant tapes are available in thicknesses from 50 µm to 200 µm. The soft PET and non-woven backing make it suitable for lamination applications with flame retardant requirements. The high performance acrylic adhesive mass makes the products optimal for various applications with low carrier thicknesses. | |

| Advantages |

| |

| General applications |

| |

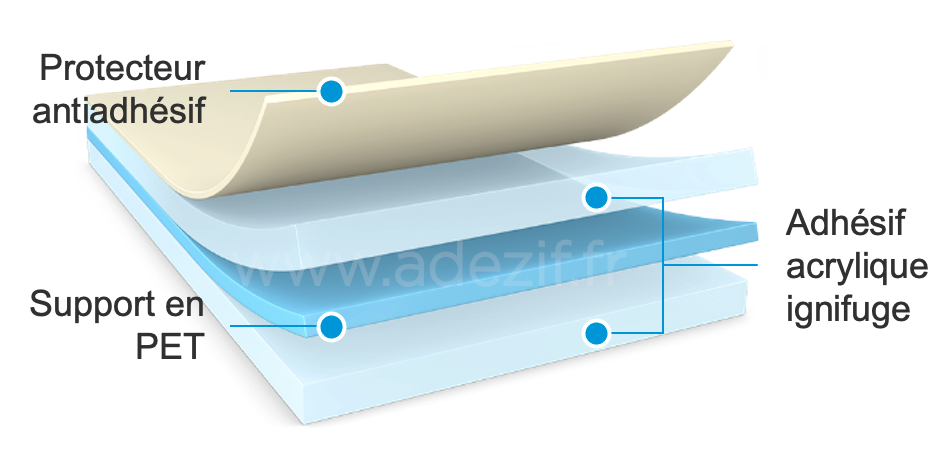

| Types of thin double sided tapes | Polyester film tape (PET)

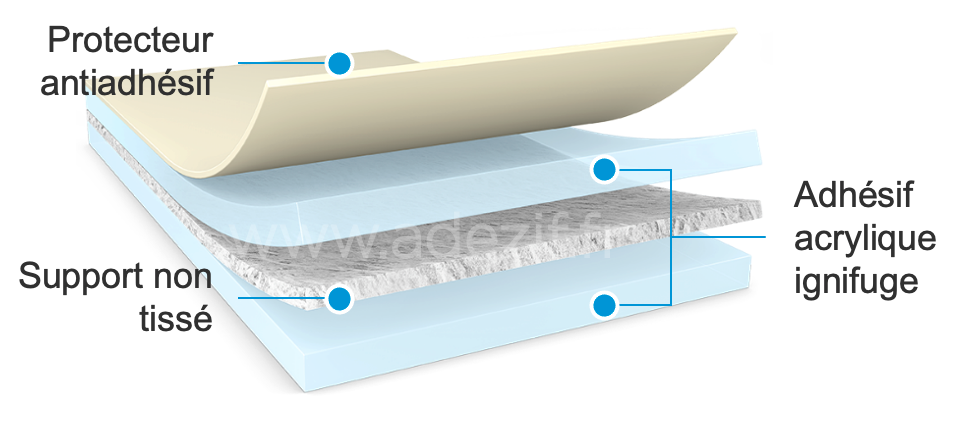

| Ruban non tissé

|

| Schemes |  |  |

| Features | Reliable adhesion to metals, coated materials, glass and many plastic surfaces. Resistant to ageing. Flexible. Efficient processing. Good choice for standard fastening applications with flame retardant properties. | Good adhesion to metals, coated materials, glass, etc. Resistant to ageing. Flexible. Efficient processing. Very good conformability to uneven shapes during lamination. Good choice for standard lamination applications with flame retardant properties. |

| FLAME RETARDANT POLYETHYLENE (PE) DOUBLE-SIDED TAPES | |

|---|---|

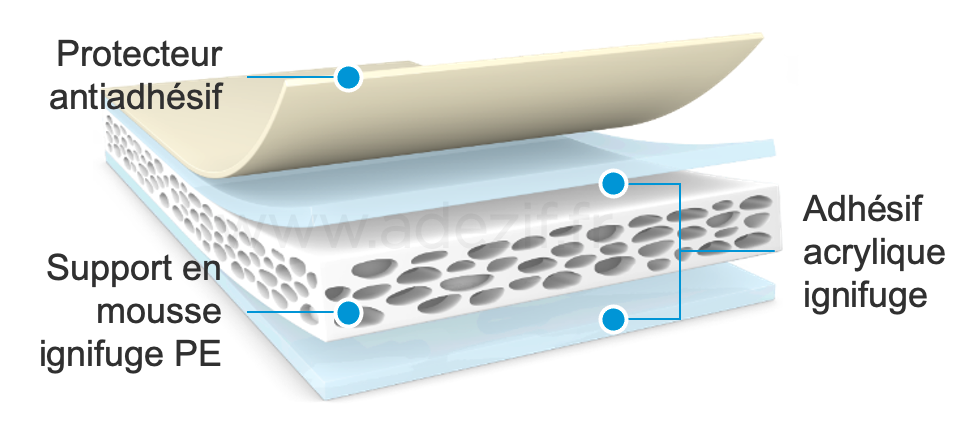

| Scheme |

|

| Description |

|

| Main applications |

|

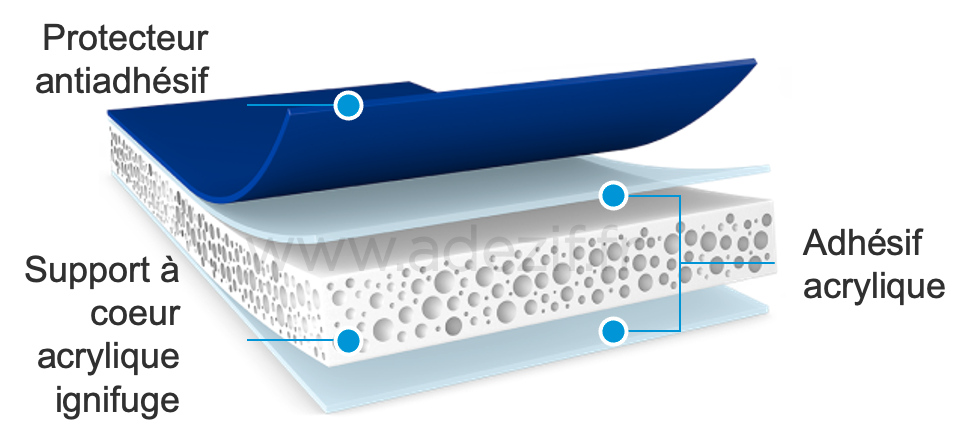

| DOUBLE SIDED FIREPROOF ACRYLIC CORE TAPEE (VISCOELASTIC ACRYLIC FOAM) | |

|---|---|

| Scheme |

|

| Description |

|

| Main applications |

|

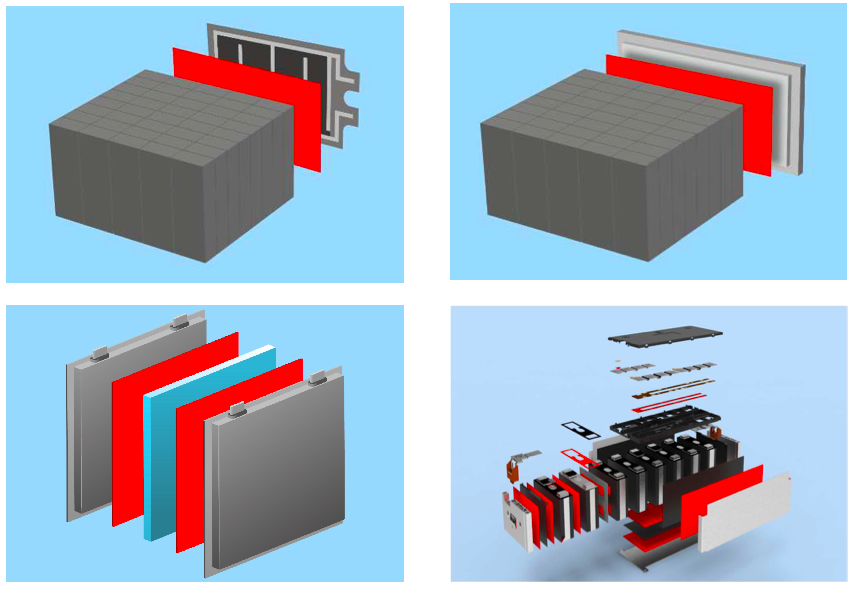

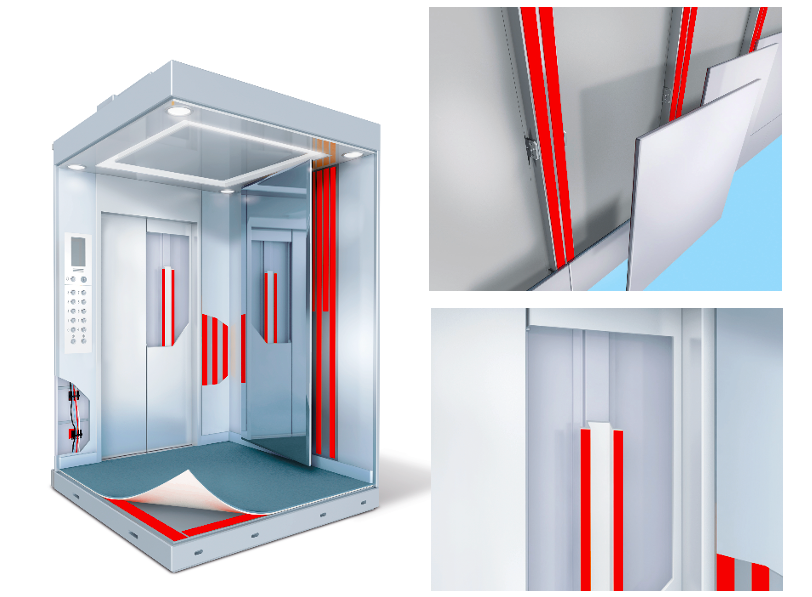

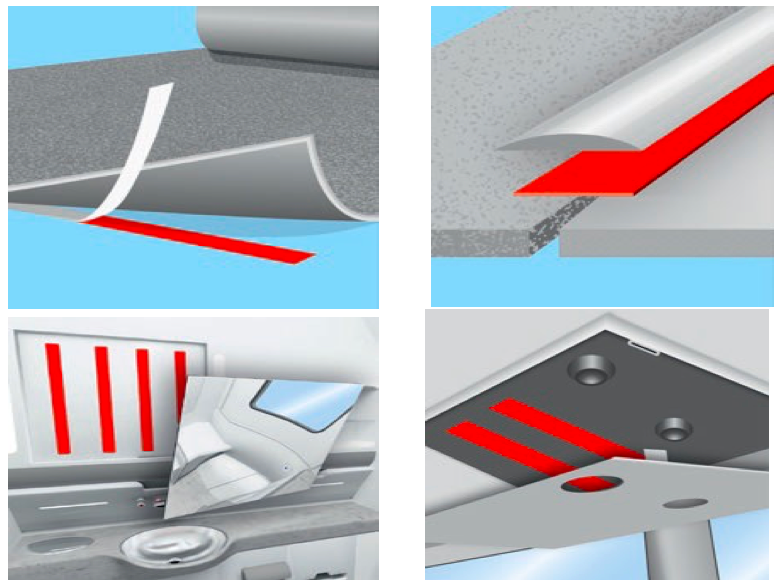

Industries and applications using flame retardant solutions

Flame retardant and halogen-free adhesive tapes are used by many industries to contribute to passive fire protection.

| APPLICATIONS | REGULATORY REQUIREMENTS (STANDARDS) | ||

|---|---|---|---|

| AUTOMOTIVE |  |

|

|

| CONSTRUCTION/BUILDING |  |

|

|

| TRAINS/TRANSPORT |  |

|

|

| MARINE/NAVY |  |

|

|

| HOUSEHOLD APPLIANCES |  |

|

|

Other fields concerned: special vehicles, electronic devices, signalling...

Fireproof liquid adhesives and sealants

Fireproof glues and sealants play a crucial role in designing fire-resistant buildings and equipment.

Fireproof glues are formulated to withstand extremely high temperatures and fire. They must be capable of enduring temperatures sometimes as high as 1000°C for extended periods without degrading or losing their adhesive strength. These adhesives are also resistant to chemicals, moisture, UV rays, and wear.

Fireproof sealants, like the Sikaflex 821 FR special train PU fire sealant, are used to fill gaps between elements (doors, windows, etc.) to prevent or slow down the spread of fire. They are typically made from special materials such as silicone or elastomer. These sealants must be able to withstand fire for a prolonged period while maintaining their seal to prevent the spread of flames. They also need to be capable of accommodating structural movements, such as expansion and contraction, without losing elasticity.

Fireproof adhesives and sealants are used in applications like fire doors, curtain walls, ventilation ducts, and smoke evacuation systems. Due to their ability to resist fire and protect structures from fire hazards, they are essential for fire safety in the industry.

Like fireproof tapes, they must comply with fire safety standards and regulations, such as ASTM, UL, and EN standards.