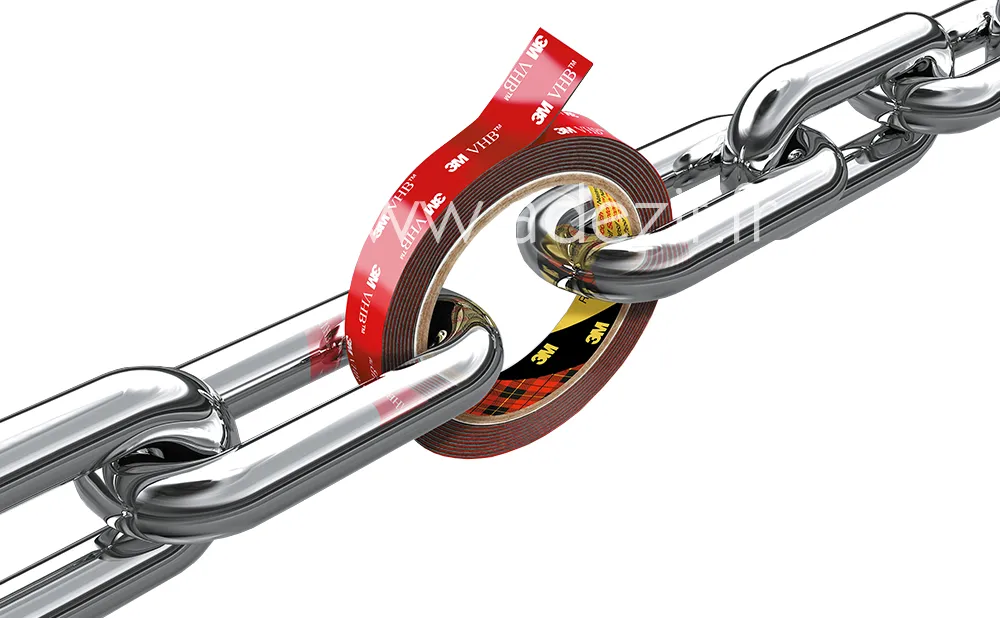

3M VHB double-sided adhesive tape

- Very high performance bonding

- Absorbs deformation and shocks

- Replaces mechanical fasteners: rivets, screws, welding

- Assembly of different materials

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Description of 3M Very High Bond (VHB) double-sided adhesive tape

VHB tape developed by the company 3M is an excellent solution for replacing mechanical fasteners. It’s a technology marketed by the company 3M that differs from standard double-sided foam tape. It consists in 100% acrylic foam adhesive and allows for high performance assemblies.

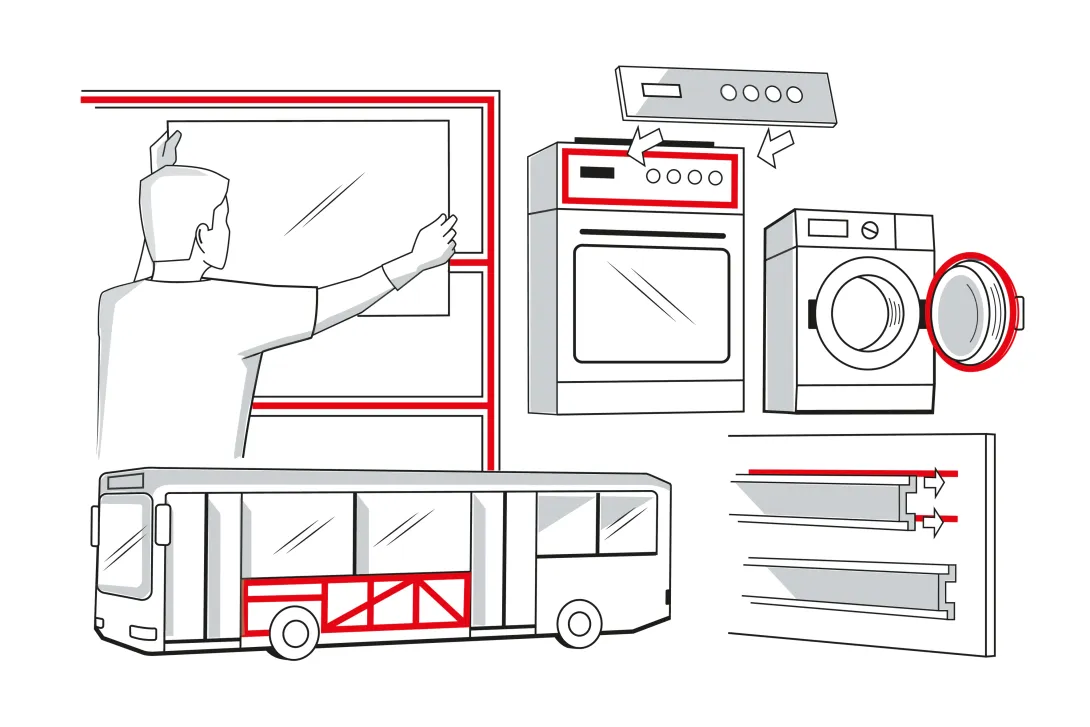

It is easy to use on different materials and meets aesthetic needs on your products (no screws, joints, welding, rivets…). This acrylic foam tape can absorb peeling stress, tension, shearing and splitting. It is used in many areas like : construction (with STCB and ETA certification), the aeronautical industry, commercial signage, doors, windows, appliances.

It is used to assemble many types of materials like acrylic (PMMA), polycarbonates (PC), painted surfaces (epoxy paint).... These products have proven themselves for over 30 years !

Some tips for choosing your VHB 3M ?

VHB is a registered trademark of 3M, like scotch. There are many references of VHB. Ask about an assessment for your application !

For a low temperature application, use our specific reference that can be applied on cold surfaces.

If you use epoxy powder coating or polyester : Some VHB can be painted during a powder coating cycle, or bond directly on powder coating.

Some examples of applications of 3M VHB tape ?

Installation of transparent displays or signage

Process for applying VHB

Check out our detailed guide for precise application of 3M VHB tapes.

Degreasing, dust removal

Applying primer

Application of VHB (example of recommendation: 60cm² per Kg static load)

Marouflage

Assembly

Pressurization (1Kg/cm²)

Some examples of our VHB references

Strong bonding on high surface energy surfaces. Viscoelastic. Very high temperature resistance

Assembly of metal parts before powder coating cycle. High bonding properties. Excellent resistance to heat

Suitable for glass and plastic. Clear. Custom die-cut

Cold application (0°C). Conformability of product. Resistance to solvents

Resistance to chemical products : diesel, acetone, methyl ethyl ketone. Durable resistance outdoor. Excellent resistance to UV

High environmental performance. Adhesion on many surfaces. Resistance to plasticizer migrations

Adhesion on powder coating. Without surface preparation. Good temperature resistance

Short-term temperature resistance up to 230°C. Very versatile and multi-surface. More affordable than standard VHB tape

Low surface energy bonding. Ideal for composites and plastics. No primer or surface preparation. Instant tack, extreme durability.