Custom lamination of material

- Lamination in small and large widths

- Infinite combination of surfaces

- Custom product and bonding

Quote

Close

Get a quote for this product

Would you tell us more ?

Step 2/2

back

Thank you !

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Overview

Lamination

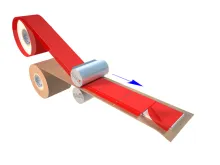

Lamination operations consist of laminating two materials to each other. So we start with 2 different products to create one unique product that can present the benefits of the two combined materials. This allows us to be the manufacturer of a product that has unique properties.

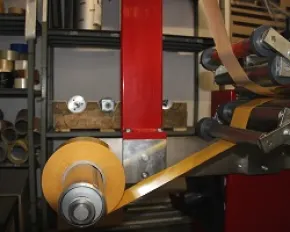

Our fleet of machines enables us to do lamination on widths from 50 mm to 1,500 mm wide on several materials including some of the following examples :

- Polyethylene film

- Polyester film

- Cotton cloth

- Thin neutral foam

- Rubber strip

- Non woven rolls

- Felt

- Abrasive strips

- .... and many others

The main advantage of lamination is that you can add a feature that the base material does not have.

Here are the main ones :

- Mechanical resistance : If you use an adhesive product that has weaknesses during tensile or shear movements, we can laminate it with a reinforced or cloth to overcome this weakness

- Adhesion : If the products you use don’t have good adhesive material and your volume is too low to do custom coating, we can bond a high performance double-sided adhesive on your product

- Electrical conduction

- Thermal conduction : To allow heat dissipation and prevent overheating

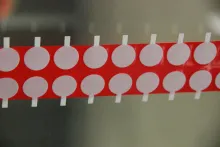

- Reel detection : To have an adhesive tape that is double-sided and can also be detected during splicing (metallic, photoelectric…)