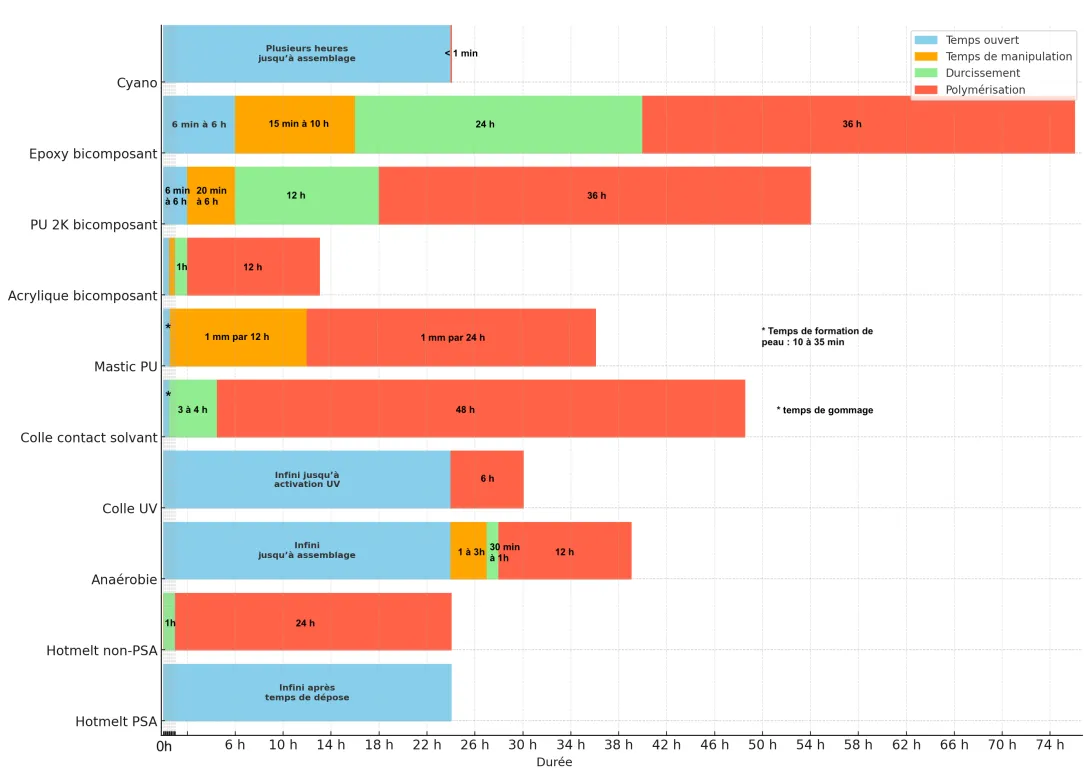

Adhesion times of industrial adhesives: from open time to polymerization

- Expertise in bonding times

- Comparison of each adhesive type

- Production rate optimization

- Support in choosing the right adhesive

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Why understand the curing process of an adhesive?

In industrial bonding, every second matters. To ensure performance, safety, and long-term durability in your applications, it's crucial to understand the reaction times of adhesives.

Open time, handling time, curing time... Mastering the different reaction phases of an adhesive helps you:

👉 Avoid bonding defects caused by too short or too long working times

👉 Minimize production downtime

👉 Ensure final quality, especially on difficult materials or critical parts

🔍 Examples of challenges:

Bonding hoods in the automotive industry: a two-component epoxy adhesive with too short a working time cures in the mixer before application is complete.

Mounting sandwich panels in construction: poorly managed open time leads to loss of adhesion if panels aren't positioned quickly enough.

End-of-line packaging: underestimated handling time can cause parts to shift or deform during packaging.

In automotive manufacturing, a fast-curing structural adhesive helps release tooling more quickly.

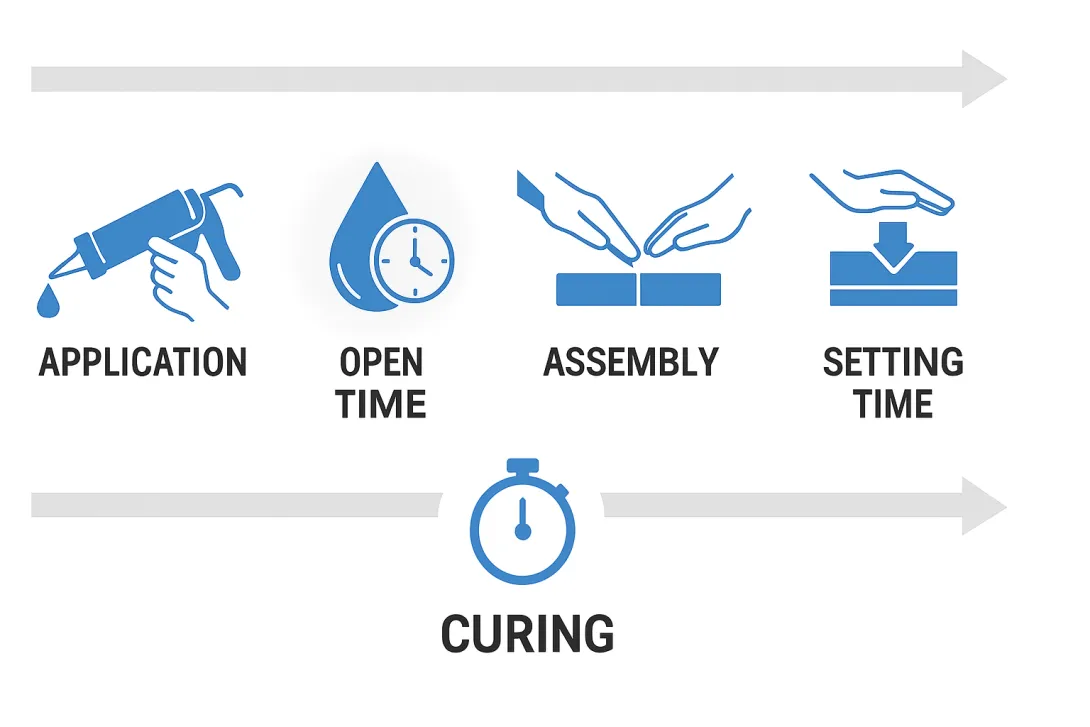

Key stages leading to full adhesive polymerization

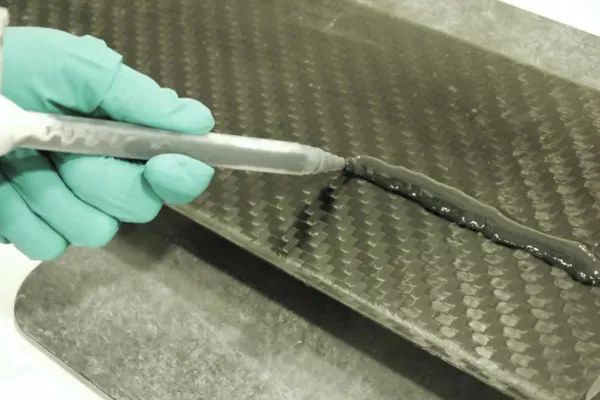

| Open time / Working timeThe open time, or working time, refers to the period between the application of the adhesive and the moment it starts to react. During this window, the materials can be adjusted or repositioned before polymerization begins.

🔎 Note: In most cases, open time and working time are used interchangeably. However, some manufacturers differentiate these terms for two-component adhesives:

|

| Tack time / Flash-off timeTack time refers to the moment when the adhesive becomes tacky but not dry. This phase is typical for contact adhesives and solvent-based glues. It's the critical point when the two surfaces must be joined. |

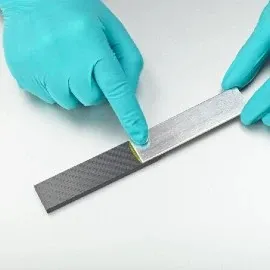

| Set time / Handling timeSet time is the time required for the adhesive to reach a mechanical strength sufficient to hold the bonded parts together without external force. This is when the adhesive starts to resist stress, allowing safe handling of the assembly. |

| Cure time / Full cure timeCure time is the period needed for the adhesive to reach 90% of its final mechanical properties. This usually takes a few hours, depending on the formulation. |

| Final polymerizationPolymerization time refers to the total duration required for the adhesive to reach its maximum mechanical performance. This can range from several hours to several days, and is typically longer than the cure time. |

🔎 Please note

Technical terms related to adhesive bonding times may vary from one manufacturer to another. Some brands use specific terminology or slightly redefine these concepts. The definitions provided here are based on the most widely accepted standards in the industry to ensure clarity and comparability.

Choosing the right adhesive based on time constraints

📌 Important: The values below are indicative and may vary depending on application conditions (temperature, humidity, adhesive thickness, substrates, etc.) and manufacturer formulations. For accurate data, refer to the technical data sheet or contact us.

| Adhesive type | Open time | Handling / set time | Cure time (90% properties) | Full polymerization |

|---|---|---|---|---|

| Cyanoacrylate | Several hours until bonding (varies) | < 1 min | ~30–60 sec | < 1 min |

| 2-part epoxy | 6 min to 6 h depending on type | ~15 min to 10 h | ~24 h | ~36 h |

| 2-part polyurethane | 3 min to 2 h | ~20 min to 6 h | ~12 h | ~36 h |

| 2-part acrylic | 2 to 30 min | ~5 min to 1 h | ~30–60 min | ~12 h |

| Solvent-based contact | 15–30 min (tack time) | Immediate | ~3–4 h | ~48 h |

| UV adhesive | Infinite until UV activation | Immediate under UV | Immediate under UV | ~6 h |

| Anaerobic adhesive | Infinite until bonding | ~1 to 3 h | ~30 min to 1 h (varies) | ~12 h |

| PSA hot melt | Infinite after application | Not applicable (remains tacky) | — | — |

| Non-PSA hot melt | < 1 min | < 2 min | ~1 h | ~24 h |

| PU sealant | 10–35 min (skin formation) | 1 mm per 12 h | — | 1 mm per 24 h |

At Adezif, our added value is built on a technical and tailored approach, fully aligned with your production requirements:

A detailed analysis of your production cycles

In-house testing with your materials in our lab

Custom adhesive solutions with samples for trials

Technical support and a wide range of adhesives