UV curing lamps and systems

- Essential equipment for UV curing

- High performance technologies, UV bulb or LED

- Various devices adapted to your applications

- Easy to use, fast curing

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

What are UV curing systems ?

Adezif offers a range of UV curing equipment for UV curing adhesives, i.e adhesives containing photoinitiators. The UV light or visible light emitted by these devices triggers the photopolymerization of the adhesive, also known as "radiation curing".

UV curing is a method frequently used for assembly applications where flexibility, mechanical strength and transparency are required:

- Glass industry, POS, medical or optical equipment, electronics, household appliances, aeronautics...

- Assemblies with at least one UV-transparent material: glass-glass, glass-plastic, glass-metal...

This process requires little working space and is much faster to set up than thermal curing, which allows industrial operators to gain considerably in productivity and quality control.

There are two main types of UV curing technology :

- Bulb technology: "traditional" UV lamps and equipment

- LED technology : More and more popular in the industry, LED UV curing lamps allow an efficient curing of adhesives and have a much longer life span (on average, 20000 hours vs. 1000 hours for bulb devices)

Adezif provides UV-A, UV-B, UV-C and visible light curing systems, suitable for both manual applications and assembly lines.

How to choose your UV curing machine ?

Three key parameters to choose you UV curing lamp:

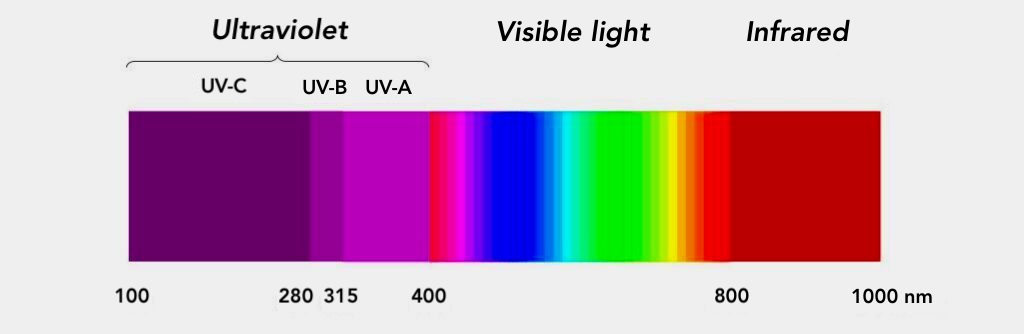

UV spectrum:

It must target the photoinitiators contained in the UV curable adhesive. There are three main wavelengths:

- 352 nm (UV-A)

- 365 nm (spotting, deep polymerization)

- 405 nm (surface mechanical strength).

Always test before final bonding. Even a multi-purpose UV lamp may be more or less effective for a particular spectrum and depending on the adhesive.

Surface specifications:

- Choose your UV lamp or curing unit according to the dimensions of the bonding surface. Regular exposure ensures even curing and avoids creating tensions or defects in the final assembly.

E.g.: UV light projectors are suitable for short lengths. UV tubes are made for longer surfaces.

- Check the transparency and properties of the materials you wish to bond. Some plastics, such as polycarbonate or PMMA, may have an anti-UV treatment, which slows down or even prevents polymerization.

Properties of the adhesive used:

See the page about our industrial UV cured glues and adhesives.

Examples of UV/LED equipment for industry

UV/LED systems for large surfaces

| Large format UV curing chamber High intensity UV chamber, for use on a work surface or in tunnel version for integration in an automated production line.

| Get a quote in 24h |

| Small size LED dispatching system / LED UV curing box Ideal for small to medium productions. | Get a quote in 24h |

Single-point curing systems

| UV fiber optic system High intensity system, frequently used in the industry. It is assembled with the appropriate optical fiber. | Get a quote in 24h |

| UV LED curing station LED controller that can be equipped with one or more individual LED heads corresponding to the required wavelengths. | Get a quote in 24h |

| Handheld UV curing light Portable UV/visible light source, designed for the production of small series and small assemblies. Battery or mains operated. | Get a quote in 24h |

| LED rail light For high speed production lines. The narrow profile of the LED head requires minimal space. | Get a quote in 24h |

Additional accessories

| Dosimeter-radiometer Measures the light dose and light intensity of the UV curing equipment. For applications requiring a high quality monitoring (e.g. medical, aeronautics) | Get a quote in 24h |

| Single-point radiometer Electro-optical instrument designed to measure and display the density of UV radiation emitted by a UV optical fiber. | Get a quote in 24h |

| UV protection glasses Grey : UV-A and UV-C Orange : Visible light | Get a quote in 24h |

Some of our references

Lightweight and cordless for small manual assemblies. Kit with all power and safety accessories. LED technology: powerful, low power consumption, long service life.