Splicing in industry

- Splicing in industry

- Resistant to mechanical traction

- Can be thermoformed

- Detectable by photo-cell

Quote

Close

Get a quote for this product

Would you tell us more ?

Step 2/2

back

Thank you !

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Overview

The applications for splicing with adhesive tape

Almost all industries that use material in rolls use single sided or double-sided adhesive tape for splicing operations. There are a variety of splicing applications, and they can be subjected to different constraints.

The main splicing applications are :

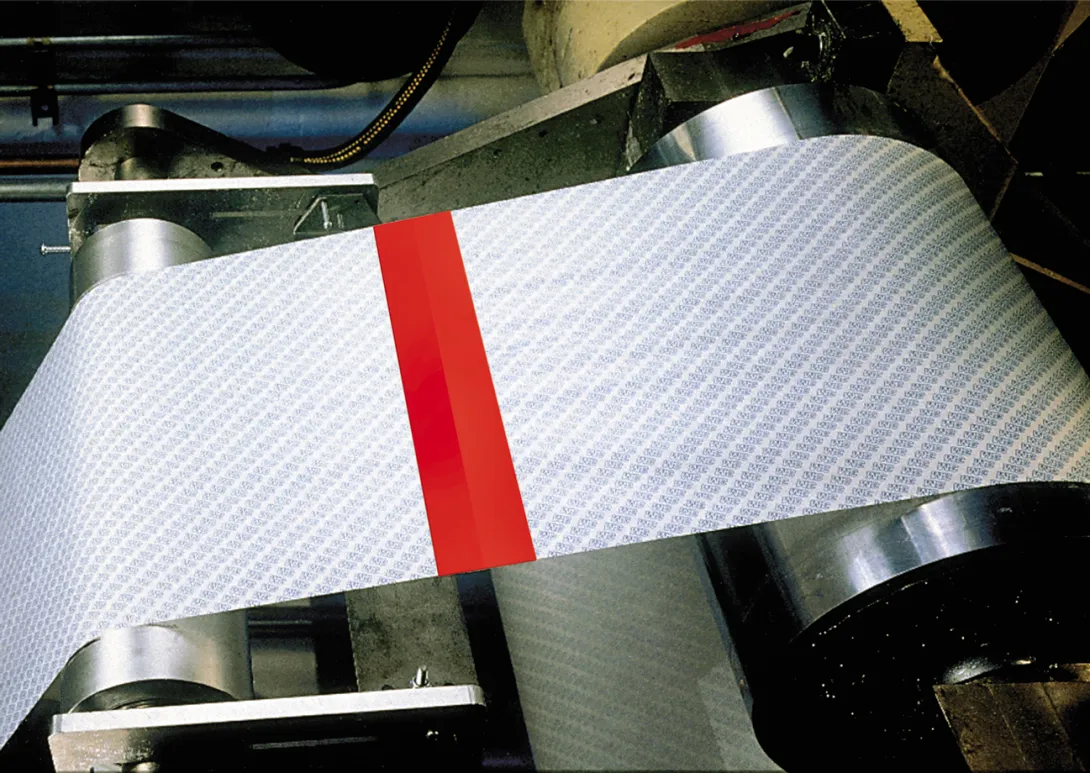

- Flying splicing : The cardboard and paper industries use adhesive tape for splicing Kraft paper that is used for the manufacturing of corrugated cardboard. These tapes resist the high temperatures used for these operations. Some repulpable adhesive models enable you to recycle the paper and cardboard ends and where the splice has been made.

- Thermoformable splicing : Thermoformable single sided and double-sided tapes enable you to splice thermoformable foil used for the manufacturing of containers and blister packs, especially in the food and pharmaceutical industries.

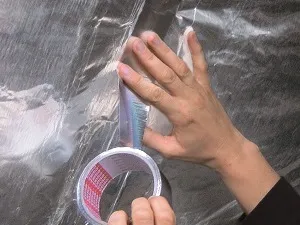

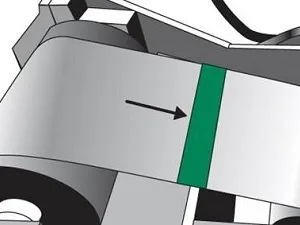

- Visually identified splice or by cell : Splicing is necessary in many industries, but it is also often necessary to identify them later. Coloured or metallic single sided adhesives enable easy visual identification or use of a detector. There are also double-sided colour tapes, as well as double-sided metallic tapes for these applications.

- Splicing paper and silicone-coated film : Splicing paper and silicone-coated film requires the use of a specific adhesive. The significant tensile strength the splicing is subjected to requires high performance products.

- Cloth splicing : The procedures for manufacturing cloth, especially coated cloth (tablecloths, oilcloth, technical cloth…) can be improved by the use of very technical adhesive solutions suitable to the tensile stress and temperature constraints of these industries.

The main splicing adhesives

- Single sided polyester adhesive tape : High temperature resistance, available in several colours and aluminium-coated, thin tape (Example: Scotch 850 splicing adhesive)

- PVC adhesive tape : For thermoformable splicing

- Bi-directional filament tape : Economical, excellent mechanical resistance (For example: CT 77 filament tape)

- Non woven double-sided adhesive tape : Economical, easy to use