Final assembly / Permanent bonding

- Permanent and resistant assembly

- Replace mechanical fastenings

- Bonding of different materials

- Long-lasting assembly

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Description of the application

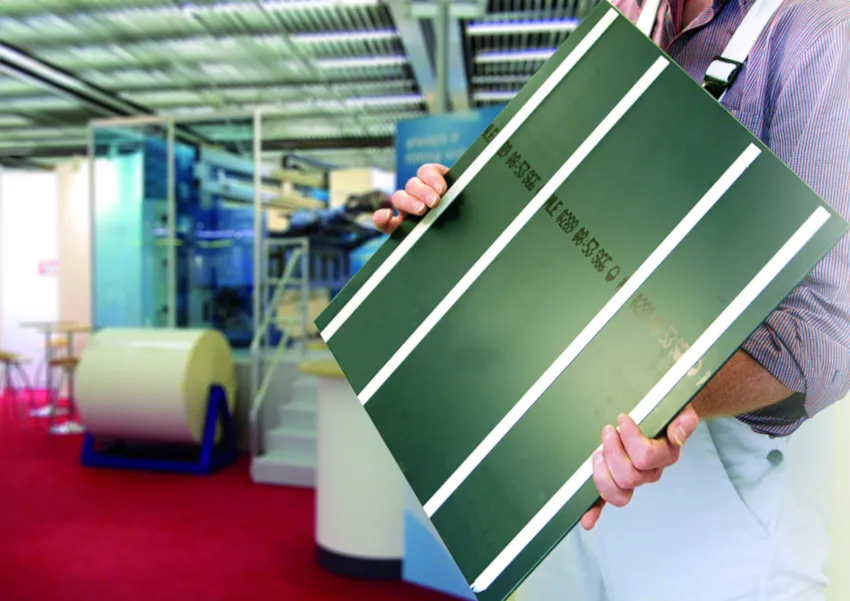

Final assembly is widely used in many industries : POS, the aeronautic industry, the printing industry, Industry,… And there are many solutions for assembling two parts for an effective and sustainable assembly.

There are two main categories of final assembly :

Outdoor assembly or bonding

Bonding and fixing in an outdoor environment require high performance assembly that can resist against environmental constraints: temperature, wind, moisture, presence of solvents…

Most often structural adhesives are used, and we can also recommend acrylic foam tape, which is designed to last outdoors. It is essential to dimension the assembly surface to create an optimal and effective sealing surface. Learn more about effective bonding !

We speak about structural bonding when the assembly has high stress and the adhesive applied on steel develops performances higher than 70 Kg/cm² or 7 Mpa.

Indoor assembly or bonding

In this category, we rank all the bonding that is not subjected to extreme constraints or a difficult environment. For example : paper/paper bonding or PVC/Aluminium for indoor POS displays. This type of bonding is generally more suitable for adhesive tapes that are used to facilitate the application process. The main difficulty is choosing the best material (PVC, Cloth, Polyester, Polypropylene....) and the right adhesive (rubber, acrylic, silicone) depending on the constraints of your assembly.

The main products used for final bonding

Depending on the materials to assemble and their surface energy, here is a list of the main products used in industry for final bonding and structural bonding :

Examples of permanent assemblies

Permanent, discreet and transparent bonding. Securely bond glass, wood or plastic with an elastic adhesive solution.

Adhesives, glues, and sealants for various surfaces. Long-lasting strength, seamless finish, easy application.

Weld-free repair, long-lasting durability, corrosion protection, OEM-approved products.

Thorough surface preparation. Adhesives suitable for composites. Resistance to shocks and vibrations. Solutions for structural bonding