LD3000 Electric dispenser for adhesive die-cuts with liner scrap rewinding

- Productivity gain for mass production

- Auto liner separation and recovery

- Compact: great comfort

- Accessory: TDSTAND03 for large rolls

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Description of LD3000, automatic dispenser for adhesive die-cuts

The LD3000 is an electric dispenser designed for high-speed automatic dispensing of adhesive die-cuts.

It is especially designed for dispensing small-format tags, labels and die-cuts, such as barcode rolls, packaging labels, etc. Thanks to an integrated and adjustable photoelectric sensor, the industrial operator can determine with the highest precision the output of his adhesive die-cuts.

With its high torque motor, the LD 3000 automatic tape dispenser is suitable for all types of adhesive die-cut tapes. It can handle rolls up to 152 mm outside diameter and from 6 to 57 mm wide. The diameter of the core is 76 mm maximum.

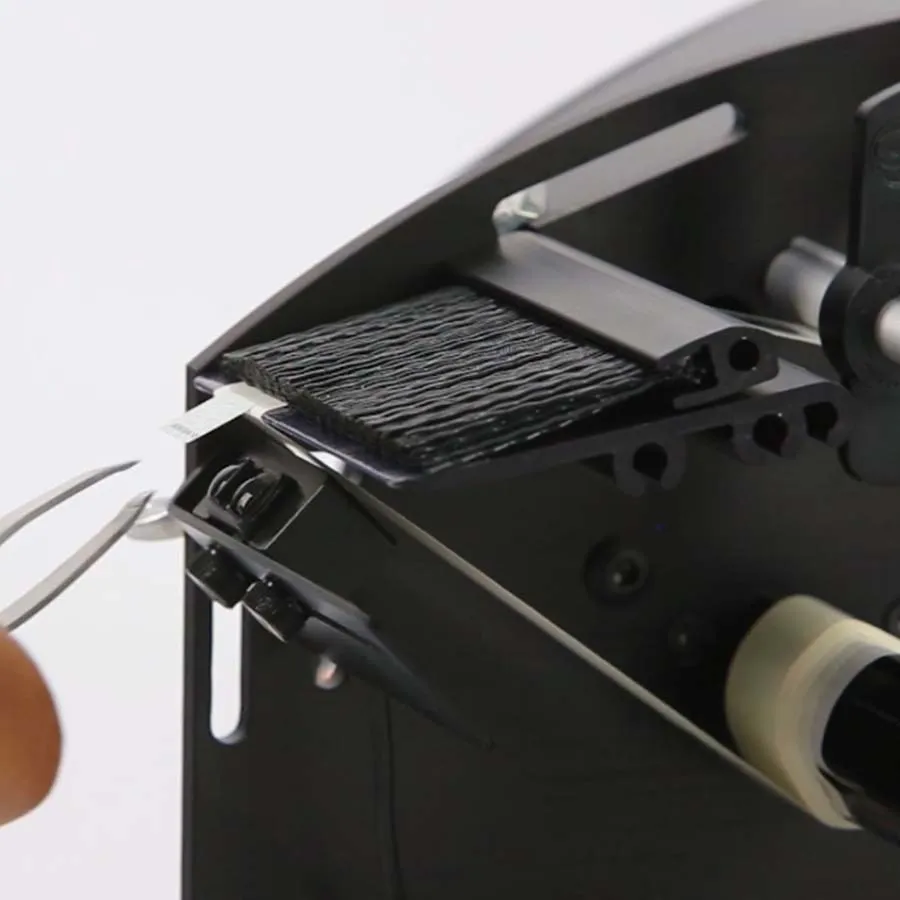

This automatic dispenser of self-adhesive die-cuts is also equipped with an adjustable braking brush to regulate the pressure exerted on the die-cuts. This allows to optimize the separation of the die-cuts from the liner protector, according to the type of roll, materials used, etc.

Main features:

- High speed (56 mm/s) automatic dispenser for adhesive die-cuts

- Compact: ideal for small work areas

- Adjustable pressure rollers

- Automatically lifts pads from the liner and feeds them forward

- Dispenses adhesive labels and die-cuts

- Accurate and reliable photodetector

- Anodized aluminum construction

- Dispenses die-cuts from 6 to 57 mm wide / 6 to 76 mm long

- Fits 25 mm and 76 mm cores

- Automatic rewinding of liners for a cleaner working environment

- Easy recovery of liners

- No tools required to adapt to different die-cut sizes

- No maintenance required

Advantages of the automatic adhesive die-cut dispenser LD3000

Increased productivity

The LD3000 manages the dispensing process of the adhesive die-cuts automatically, from A to Z: separation from the liner, advancement of the roll, dispensing of the self-adhesive die-cut, recovery and rewinding of the used liner (thanks to an integrated reel and drive rollers), presentation of the next label. The industrial operator does not have to worry about these different actions ans simply has to recover the adhesive ide-cut part. The LD 3000 thus offers a gain in time, space, cleanliness, and productivity.

Ultra-fast and accurate dispensing

The LD3000 dispenses self-adhesive die-cuts at a high speed of 56 mm/second. It has the particularity to combine this speed with a high dispensing precision, thanks to its photoelectric detection cell. This cell detects the recovery of the adhesive pad by the user and triggers the dispensing of the next pad. This adjustable cell can be used to calculate the dispensing length according to the angle of its inclination.

Automatic separation, recovery and winding of the protector

The LD3000 automatically peels, recovers and rewinds the liner on a roll integrated in the reel. This keeps the workstation clean and effortless. This automatic dispenser of adhesive die-cuts is compatible with most liners and materials: vinyl, paper, foam, acetate, polyester...

Comfortable to use and space saving

The compact LD3000 electric adhesive die-cutting dispenser allows production/manufacturing operators to work efficiently and comfortably in a limited work area. Its small size does not detract from its high performance.

Long life span

Designed for intensive use and long production runs, the LD3000 has a heavy-duty anodized aluminum structure, which ensures excellent resistance to the extreme conditions of use that can be found in factories or manufacturing/production workshops. Its solidity protects its components from the daily aggressions of industrial activities.

How to use the LD3000 electric label dispenser?

- Place the roll of adhesive die-cuts on the core.

- Position the end of the tape under the adjustable pressure brush.

- Pull a length by removing the first cut pieces, you get a length of liner alone.

- Wrap the protector around the dedicated drive roller, then lock the device with the metal pin.

- Adjust the pressure of the adjustable brush using the metal knob on the dispensing spindle.

- Adjust the axis of the photoelectric sensor according to the length of the adhesive parts. The dispenser is ready for use.

- Press the ON/OFF button. The first die-cut is dispensed.

- Retrieve the adhesive pad and check that the second one is present again.

- Make any adjustments after turning the machine off.

For optimal use with rolls up to 508 mm in diameter, we recommend that you combine your LD3000 dispenser with the DM100 accessory, holder for large format rolls.

Maintenance

- Very resistant, the LD3000 does not require any particular maintenance.

- Check its condition regularly to avoid the accumulation of dust or other dirt.

- To purchase spare parts for this product, please contact our technical experts.

Other DAA50 models and accessories

The LD 3000 is available in several versions in order to adapt to your application and your needs.

Contact us to know the most suitable model.

- Version for wider liners: up to 66 mm

- Electrostatic dissipation version: Antistatic dispenser that protects against electrostatic discharges. Used for highly sensitive electronic equipment and certified to meet the standards of the electronics industry.

- USDA/FDA compliant and CFIA approved version: USDA/FDA compliant coating, ideal for the food and pharmaceutical industries.

- Clear adhesive die-cut version: Dispenses clear die-cuts, such as tamper evident labels, carton closure labels and other difficult clear materials. A vertical stripe plate allows for better adjustment of the photodetector for detection of transparent materials.

Many accessories are also available to optimize the use of your LD 3000, for example:

| Accessory | Description | |

|---|---|---|

| DM100 - Wide large reel stand | For cutting rolls up to 508 mm outer diameter. | Quote |

| Stand for label dispenser | Allows the operator to hang the LD 3000 to minimize clutter on workbenches and table tops. Rugged aluminum construction for stability and convenience without unnecessary weight or bulk. | Quote |

| External rechargeable battery and charger | Allows for portable use of the LD 3000 . | Quote |

Technical data

| TECHNICAL INFORMATION - LD3000 | |

|---|---|

| Colour | Black |

| Dimensions | 155 x 178 x 272 mm |

| Weight | 1.27 kg |

| Liner width | 6 to 57 mm |

| Roll external diameter | Up to 152 mm |

| Core diameter | 76 mm |

| Adhesive die-cuts lengths | 6 to 76 mm |

| Feed speed | 56 mm/sec |

| Electrical requirements | 12V DC with universal transformer 100V - 240V AC |