Plasma masking and thermal spray protection

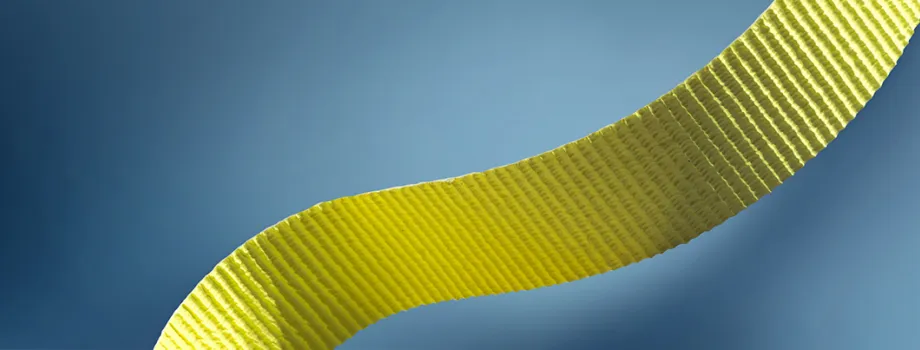

- High temperature plasma masking

- Reliable adhesion without residue

- Resistance to harsh processes

- Custom die-cutting

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

Reliable protection in extreme conditions

Plasma spray coating is a thermal spray process that deposits molten particles onto a surface to enhance its resistance or impart new properties. To achieve selective and precise coating, sensitive areas must be protected with a high temperature masking tape.

👉 Surface protection challenges in plasma spray applications:

Plasma spray surface protection involves extreme conditions:

| Requirement | Specification |

|---|---|

| Thermal resistance | Up to 315 °C |

| Adhesion | Reliable on metals, composites, and ceramics |

| Clean removal | No residue left after peeling |

| Durability | Maintains integrity throughout the entire spray cycle |

Choosing the wrong industrial masking tape can lead to coating defects and additional costs.

Applications and use cases in plasma spray coating

High performance masking tapes are used across a wide range of industrial applications:

Masking functional areas on aerospace turbines and engine components.

Protecting medical parts such as implants and prostheses during plasma spraying of biocompatible coatings.

Masking automotive components during thermal treatments and plasma coatings.

Selective coating on industrial tooling and molds.

Temporary protection of machined or polished surfaces sensitive to overspray.

Use on high-performance composites requiring effective thermal and chemical barriers.

Some specialized product ranges provide tailored performance for each stage of the process — from grit blasting to HVOF (High Velocity Oxygen Fuel) — and are qualified and approved for use in the aerospace industry, ensuring proven compliance and reliability.

Examples of adhesive tapes for plasma spray coating

| Application | Reference | Backing | Max temperature | Key features |

|---|---|---|---|---|

| Versatile plasma / grit blasting use | TV625 | Silicone-coated glass cloth | 329 °C | Plasma and thermal spray masking, strong adhesion on metal, clean removal, abrasion resistant |

| Multipurpose | 2975 | Silicone-coated glass cloth | 315 °C | Excellent balance between strength and conformability, ideal for plasma and grit blasting |

| Fast application without liner | 29A5 | Silicone-coated glass cloth | 315 °C | Self-wrapping version for easy application |

| Harsh HVOF processes | H7575 | Multilayer glass-silicone | 315 °C | Double-layer construction, single application, high durability |

| Reinforced masking | H7525 / H6595 | Multilayer glass-silicone-aluminum | 315 °C | Multilayer structure with aluminum core, reinforced strength |

| Complex geometries | 2925 | Aluminum-glass | 315 °C | Highly conformable for complex parts, clean removal |

| High purity | 2926 | Aluminum-glass | 315 °C | High-purity adhesive to prevent contamination |

| Heavy-duty applications | 6005 / 26020 | Thick aluminum foil | 315 °C | Ideal for severe plasma environments, maximum resistance |

| Cost-effective solution | 2915 | Glass cloth | 315 °C | Economic masking option for plasma and grit blasting |