Our standardized and custom adhesion tests in the laboratory

- FINAT, ISO, ASTM standardized tests

- In-house lab with certified equipment

- Tests reflecting your specific requirements

- Reports validated by the quality department

Quote

Close

You request has been sent.

We promise to respond to you in detail within 24 hours.

In the meantime, feel free to browse our other products.

IMPORTANT:

⚠️ Our adhesion tests are carried out exclusively on adhesive tapes and glues supplied by ADEZIF.

They enable us to reproduce your real application conditions and select the most suitable product for your needs.

ADEZIF does not provide testing services on external products supplied by customers.

Choosing the right adhesive for your application

Selecting an adhesive—whether a technical tape or an industrial glue—cannot rely solely on a catalog. Each application presents its own constraints: substrate type, temperature, humidity, mechanical stress, and service duration.

That’s why our ADEZIF laboratory conducts a complete range of standardized and custom adhesion tests to determine the most efficient adhesive for your specific use.

| Static or dynamic shear tests – Static or dynamic shear tests measure the mechanical resistance under parallel stress (FINAT FTM 8 and FTM 18). |

| Peel tests (90° or 180°) – evaluate the separation force according to FINAT FTM 2. |

| Pull-off tests – determine the force required to detach the adhesive perpendicularly. |

| Cleavage tests – assess lever-effect resistance (ASTM D1062, ISO 25217). |

| Tack tests (ball tack, loop tack) – evaluate instant bonding strength or initial adhesion. |

👉 Goal: provide reliable, actionable results to help you select the perfect adhesive solution for your specifications.

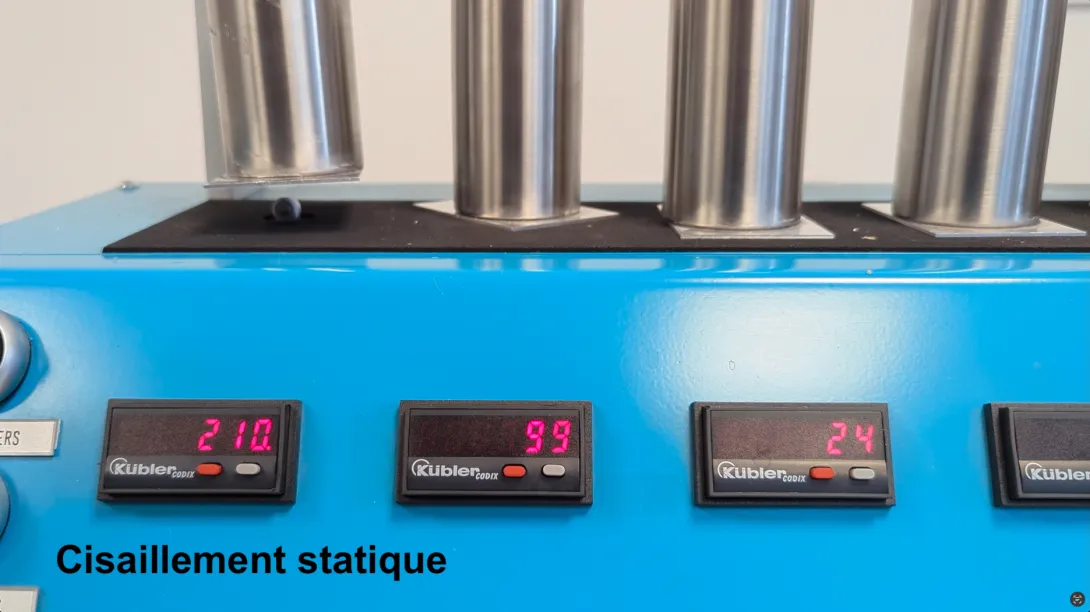

Static shear test

This test applies a fixed load to a bonded sample and measures time to failure, showing long-term performance under constant stress.

| Standard | Applications | Results |

|---|---|---|

| FINAT FTM 8 | Double-sided tapes, permanent fixations, adhesives under continuous load | Holding time before detachment, failure mode analysis |

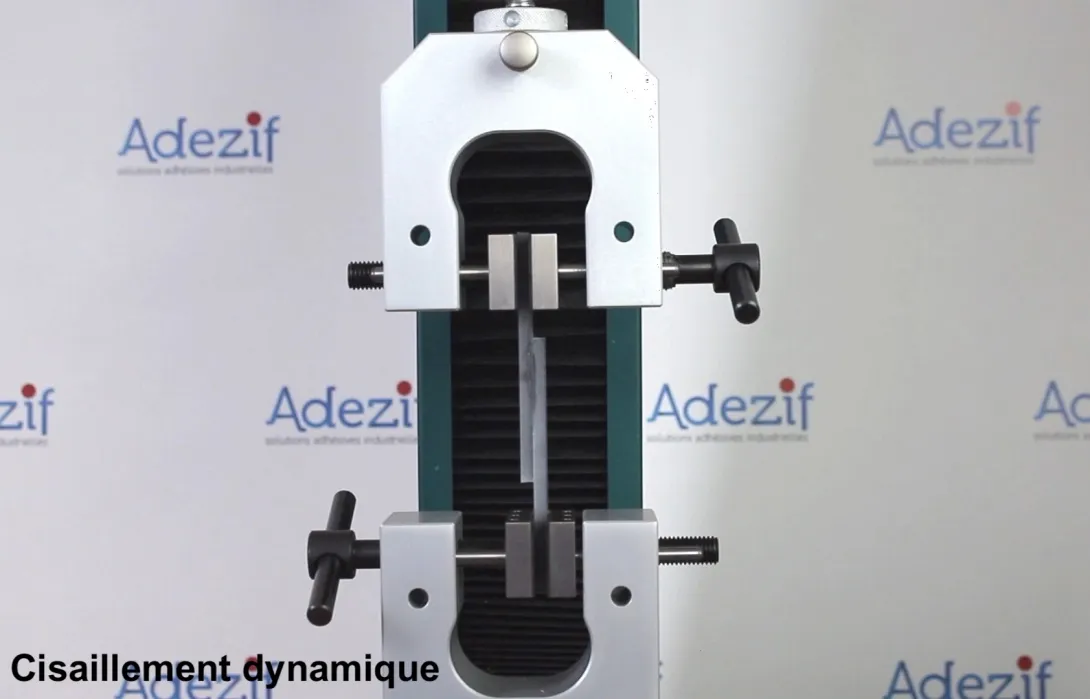

Dynamic shear test

Evaluates maximum resistance under progressive stress using a traction bench.

| Standard | Applications | Results |

|---|---|---|

| FINAT FTM 18 | Structural assemblies, high-performance glues, adhesives exposed to shocks or vibrations | Maximum force before failure, failure mode analysis |

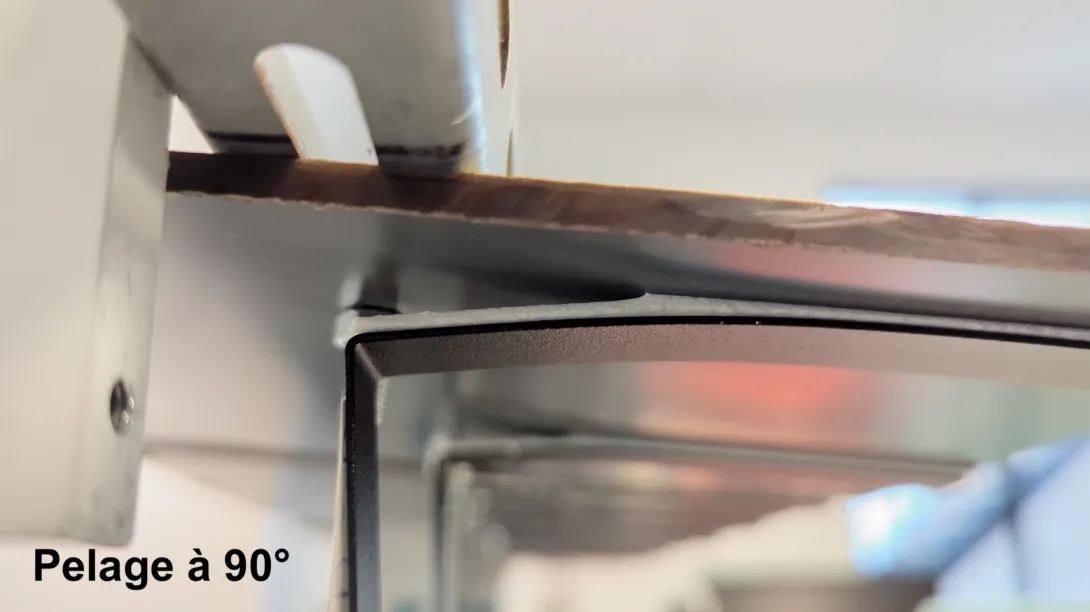

Peel test 90° or 180°

Measures the force required to remove an adhesive from a surface at a 90° or 180° angle.

| Standard | Applications | Results |

|---|---|---|

| FINAT FTM 2 | Industrial labels, technical films, mounting tapes | Adhesion force (N/cm), failure type (clean, transfer, cohesive) |

Pull-off test

Determines the force required to detach a coating or adhesive from its substrate with perpendicular tension. Especially relevant for aerospace, automotive, and construction industries, where mechanical reliability is critical.

| Applications | Results |

|---|---|

| Structural glues, adhesives on metals, coatings | Pull-off strength (N/mm²), rupture type |

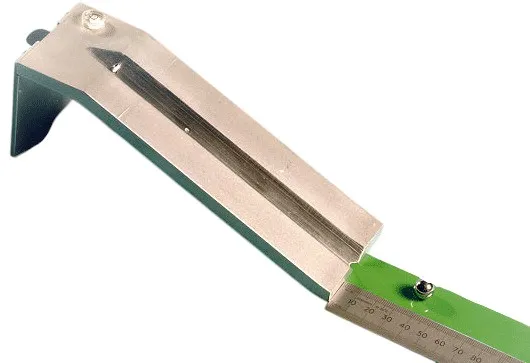

Cleavage test

Separates two bonded rigid substrates with a lever-type force, concentrating stress at the bond’s leading edge.

| Standards | Applications | Results |

|---|---|---|

| ASTM D1062, ISO 25217 | Structural adhesives, aerospace, automotive, and construction uses | Cleavage force required to initiate and propagate failure |

👉 Designed to test mechanical performance under extreme stress conditions.

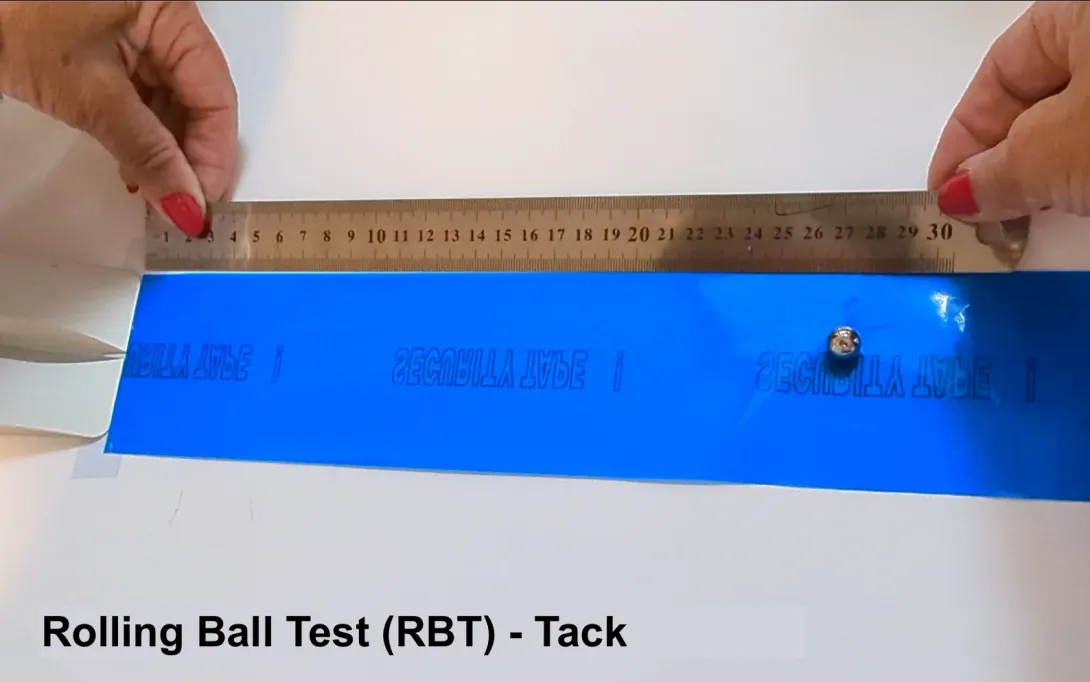

Tack test (instant adhesion)

Measures instant bonding ability when the adhesive contacts a substrate.

| Methods | Applications | Results |

|---|---|---|

| Tack loop, rolling ball test | Pressure-sensitive adhesives, repositionable tapes | Tack level based on chosen standard and method |

FAQ – Frequently asked questions about adhesion tests

What is the difference between a peel and a cleavage test?

Peel tests pull the adhesive strip at a constant angle (usually 90° or 180°) distributing force evenly. Cleavage tests use a lever force between rigid substrates, concentrating stress at the breaking point.

How do I know which test to choose?

It depends on the application: peel evaluates separation force, static shear tests long-term hold, and dynamic shear measures peak resistance. ADEZIF’s team can determine the best test or follow your specific testing protocol.

Can you test on different materials?

Yes, we test on stainless steel, aluminum, glass, technical plastics, and your own materials upon request.

Do you provide detailed test reports?

Yes, each test includes graphs, average values, and a quality analysis.

Do you perform aging tests?

Yes, we offer UV, humidity, and temperature exposure tests to simulate long-term durability.

Why choose ADEZIF for your adhesion tests?

Advanced equipment: traction benches H5KL, HR-FINAT applicators, certified software

Quality expertise: results interpreted by our quality manager

Standardized and custom protocols: FINAT, ISO, ASTM compliance with flexible adaptation

Detailed reports: force curves, rupture modes, and technical recommendations

Adhesion tests (peel, shear, pull-off, cross-hatch, tack) are essential to guarantee the performance, reliability, and durability of your adhesive solutions.

With ADEZIF, you benefit from an equipped laboratory, standardized and custom tests, and expert analysis to guide you toward the most suitable product.